The extraction tank is an extraction device that relies on gravity for natural clarification in the clarification chamber after mechanical mixing with a stirring paddle in the mixing chamber. It can also be referred to as a mixed clarification extraction tank. In recent years, the development of extraction tanks has been rapid, with their presence in various fields such as non-ferrous metallurgy, precious metals, rare earths, and nuclear industry. A wide range of extraction tanks have emerged, but those that integrate the advantages of various families are rare in the industry. Among them, the issue of how to improve the efficiency of extraction tanks is of utmost importance.

Efficiency refers to the maximum processing capacity and quality achieved by extraction tanks that occupy a small area, have a small volume, simple structure, and low cost. There are three core factors that contribute to improving the efficiency of extraction tanks, namely:

1. Improve the mixing efficiency of the mixing chamber

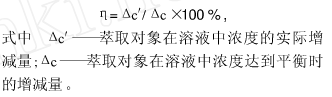

Provide maximum processing capacity for materials while maintaining high-level efficiency. The meaning of "level efficiency" is:

In industrial production, it is not economical to allow each stage of mixing to reach complete equilibrium before entering the mixing chamber over an extended period. In practice, the degree of mixing between the two phases can only approach equilibrium, and processing capacity is inversely proportional to stage efficiency. In actual production processes, finding an optimal point for extraction tank processing capacity and stage efficiency is crucial. We can provide optimization of the mixing chamber structure and agitator working methods to achieve this.

2. Improve the clarification efficiency of the clarification chamber

By optimizing the inlet and outlet flow patterns and adding auxiliary facilities, rapid and effective two-phase separation can be achieved in a relatively small clarification chamber volume.

3. Interaction between mixing and clarification

When the mixing intensity is high, the mixing efficiency increases, but clarification becomes difficult; shortening the clarification time and increasing the entrainment of the two phases will reduce the stage efficiency, so a balance between the two needs to be considered during design.