The leaching rate of nickel, cobalt, and manganese is over 99.5%

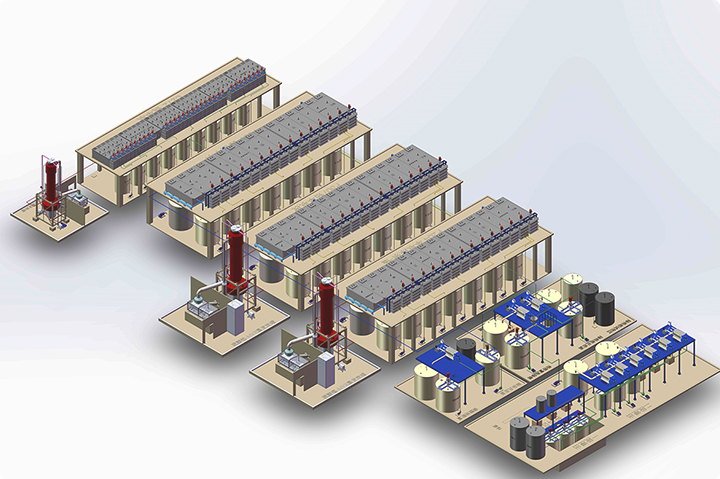

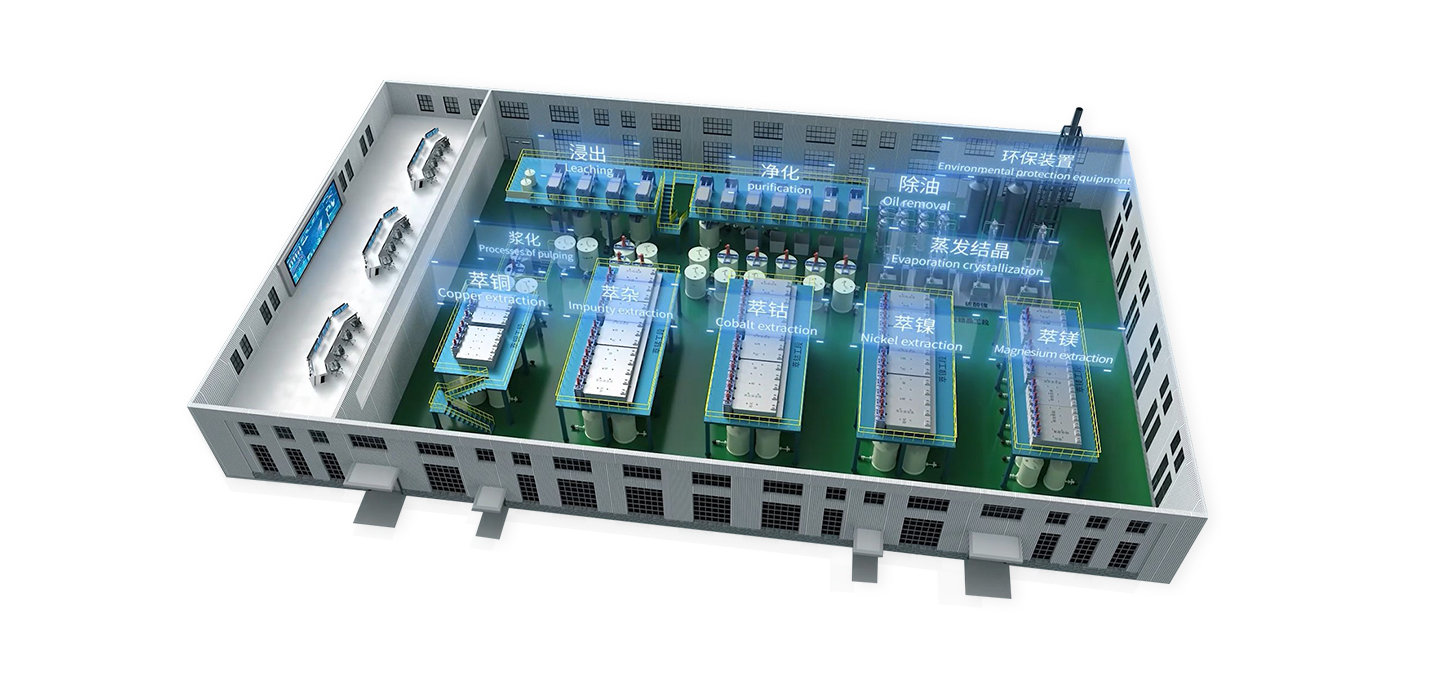

This system uses leaching residue and other washing liquids as the base solution, into which raw materials are added and stirred to form a slurry, ensuring thorough and uniform mixing of the materials. The slurry enters the leaching kettle, where relevant chemical reagents are added under certain temperature conditions, allowing valuable metals such as nickel, cobalt, manganese, and lithium to enter the solution in ionic form. The leachate and extractant enter the mixing chamber, where the copper extraction process is completed through the extraction, washing, and stripping stages. The copper-extracted stripping solution undergoes oil removal to produce relevant copper products. The copper-extracted raffinate enters the iron and aluminum removal reactor, where relevant chemical reagents are added under certain temperature conditions and the pH is adjusted, causing the iron and aluminum ions in it to form a precipitate. The slurry is then subjected to solid-liquid separation using a pressure filter.

After purification to remove iron and aluminum, the liquid is further purified through a precision filter, then cooled by a heat exchanger, and subsequently enters the extraction processes for impurities, cobalt, nickel and magnesium, magnesium, and lithium, to produce related manganese, cobalt, lithium, magnesium, and nickel products. Throughout the entire process, core parameters such as liquid level, temperature, pressure, flow rate, and pH can be monitored, and automatic detection and control functions such as acid preparation, intelligent control of the saponification process, and online detection of nickel ions can be achieved.

The leaching rate of nickel, cobalt, and manganese is over 99.5%

The lithium recovery rate can reach over 90%

Adapt to raw material fluctuations, with a nickel and cobalt recovery rate of over 98%