In the design of agitation devices for extraction tanks, pump-mixing impellers are commonly used. The type and diameter of the pump-mixing impeller directly affect operating costs and operational efficiency.

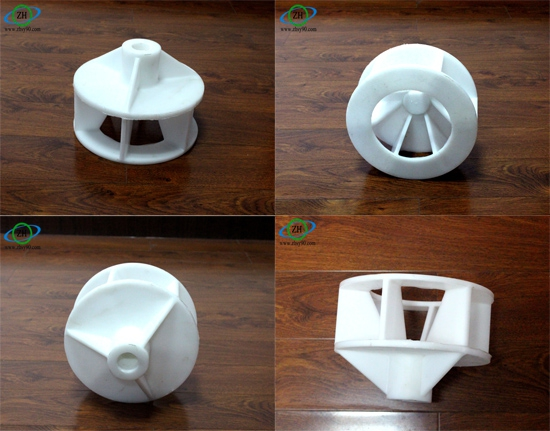

Pump impellers are classified into enclosed and semi-open types. Previously, large extraction tanks all used enclosed pump impellers, but due to their high suction force and tendency to entrain air, they are now being replaced by semi-open types, which offer a moderate suction force and lower manufacturing costs.

The design of old-fashioned extraction tanks featured an impeller diameter that was 1/3 of the mixing chamber length, which was later adjusted to 2/3 to 3/4 in practice. An impeller with a smaller diameter has a faster mixing speed and greater shear force, but the separation of the two phases during the mixing process is too fine to achieve the desired effect. Conversely, an impeller with a larger diameter has a slower mixing speed, lower shear force, and weaker suction force, but the mixing power is relatively high, leading to increased energy consumption and operating costs. Additionally, a larger impeller incurs higher processing costs and is less convenient for installation and maintenance. Based on the practice of the P204 extraction tank, it is most appropriate to set the impeller diameter to 1/2 of the mixing chamber length.